The food and beverage industry in the US has entered a decisive moment.

Consumers have long demanded natural, sustainable and clean label food and beverages and the natural color industry has grown in strength to help meet that demand. However, early last year the speed of change for food and beverage manufacturers accelerated significantly.

In April, the US Health and Human Services Secretary Robert F. Kennedy Jr. and the Food and Drug Administration expressed a wish to phase out synthetic food dyes by the end of 2026. This, together with actual and proposed bans in several US states, has suddenly given manufacturers a new challenge to face and decisions to make in a relatively short time.

Growing interest in natural

It is not just the US regulatory environment that is changing. Latin America is seeing a similar trend driven by the companies that export to the US. Several countries in the region are reviewing their legislation and considering measures that align with this shift. And the trend is being repeated in other regions – especially those exporting to the US.

Michael Kreutzer, president of Oterra US, is in daily contact with manufacturers converting to natural and has very clear advice for those with questions about the practicalities of making the switch.

“The big multinationals who have experience with natural colors want to convert as soon as possible and will definitely have a first-mover advantage in terms of access to supply, but also to the expertise necessary to do conversions,” says Kreutzer.

“We also have customers who are taking advantage of our expertise to reformulate products, but holding off on reserving product and lastly there are some customers that adopting a ‘wait and see’ attitude. All three strategies are valid, but it is clear that the later you start the conversion the greater the risks – and the chances that costs are higher and supply more limited.”

Kreutzer says there are three foundational questions that food manufacturers have to ask a supplier such as Oterra: Do you have the expertise? Do you have access to supply? And do you have access to the innovation needed to keep making progress?

Reducing complexity and making the shift to natural colors easy

“Customers rely on us to reduce the complexity of a natural supply chain, pigment choice and applications. We do that through a network of application centers in all regions around the globe. At the heart of that network are our scientists who have decades of experience in helping the world’s largest food and beverage manufacturers.”

As a company with long experience in the natural color industry, Oterra has been preparing for the changes by investing in expanding its portfolio and global footprint, most recently with the opening of a state-of-the art innovation, collaboration and production hub in Mount Pleasant, Wisconsin.

Flexibility through diversification

To convert to natural colors, first you have to make sure you have an adequate supply – and that means combining global scale with local sourcing expertise. The ramp up of demand in the US will be faster than seen in Europe. That will place a great demand on producers looking to convert – and the companies supplying them.

Natural colors are grown rather than manufactured, so the challenge for companies converting is to order early, so supply can be secured either through planting more crops or securing supply from existing or new areas.

Finding a supplier with a large portfolio of pigments and a diverse sourcing footprint means ingredients can be grown in multiple countries and regions to decrease risks. Direct contracts with farmers rather than with third-party suppliers will improve supply security further.

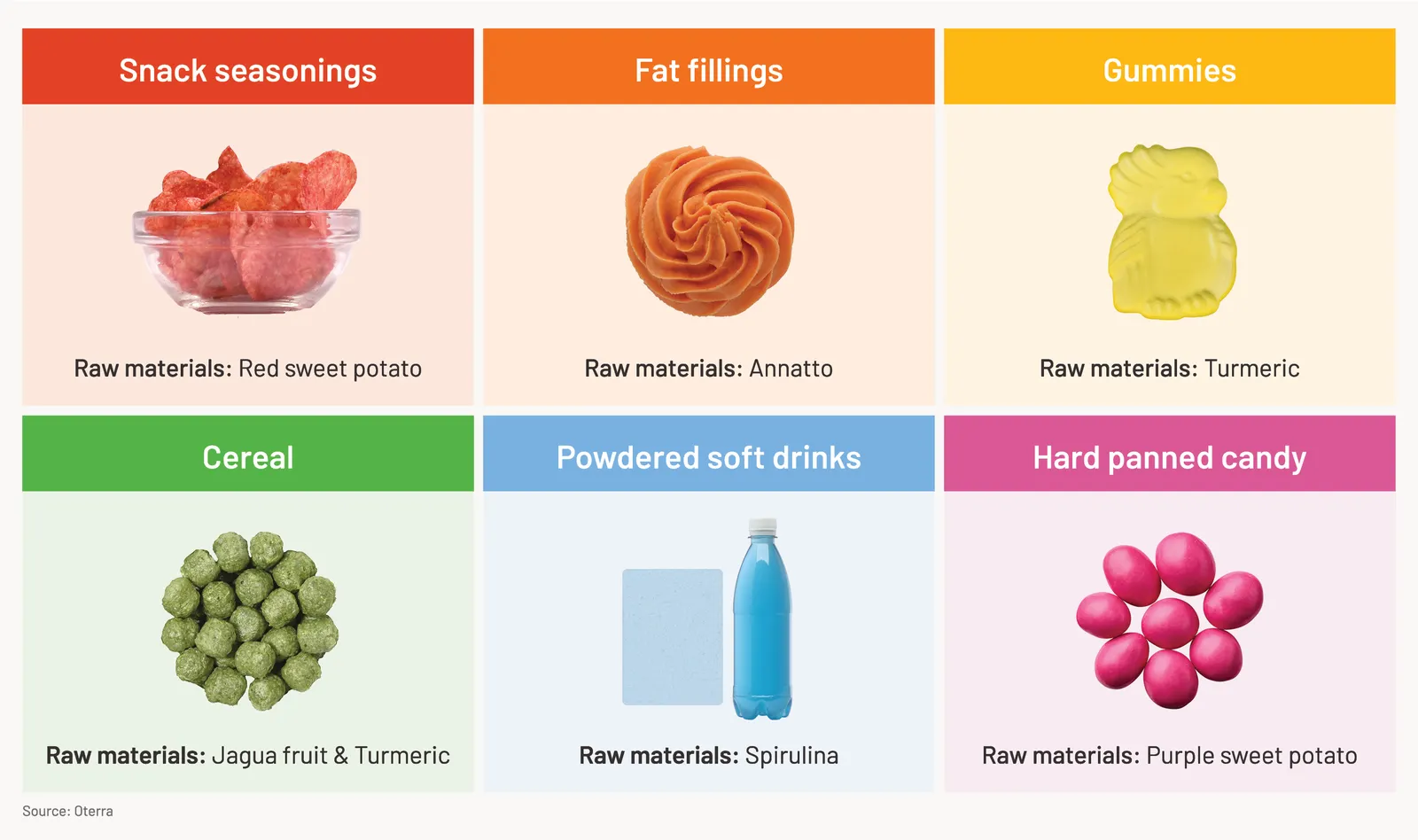

Natural color alternatives to FD&C colors in a variety of applications

The next wave of colors

Pigment innovation is the third pillar in any successful partnership. Given the rapid increase in demand, finding new plant-based raw materials, improving existing raw materials and finding new innovative processes to create colors is vital.

The FDA approved two new blues and a white in 2025, but getting a new pigment approved can be a long process. Developing existing plant varieties with higher pigment yields can help reduce cost and improve efficiency – while keeping the sourcing process sustainable and secure.

Examples of these innovations could be materials such as Oterra’s Arctic Blue spirulina, which uses pioneering production methods to cultivate spirulina 24/7 in a bioreactor, or better strains of raw materials such as the Hansen sweet potato that has been developed to produce more color units per kilo.

Ready to change

The necessity of change to natural colors from artificials feels like an unnecessary irritation to many food and drink manufacturers. But natural colors have been with us as an industry for a long time – Oterra first sold products in the US in 1876 – and there are plenty of experienced suppliers who can help, source, reformulate and innovate to meet the public demand and federal wish, for a world without artificial colors.